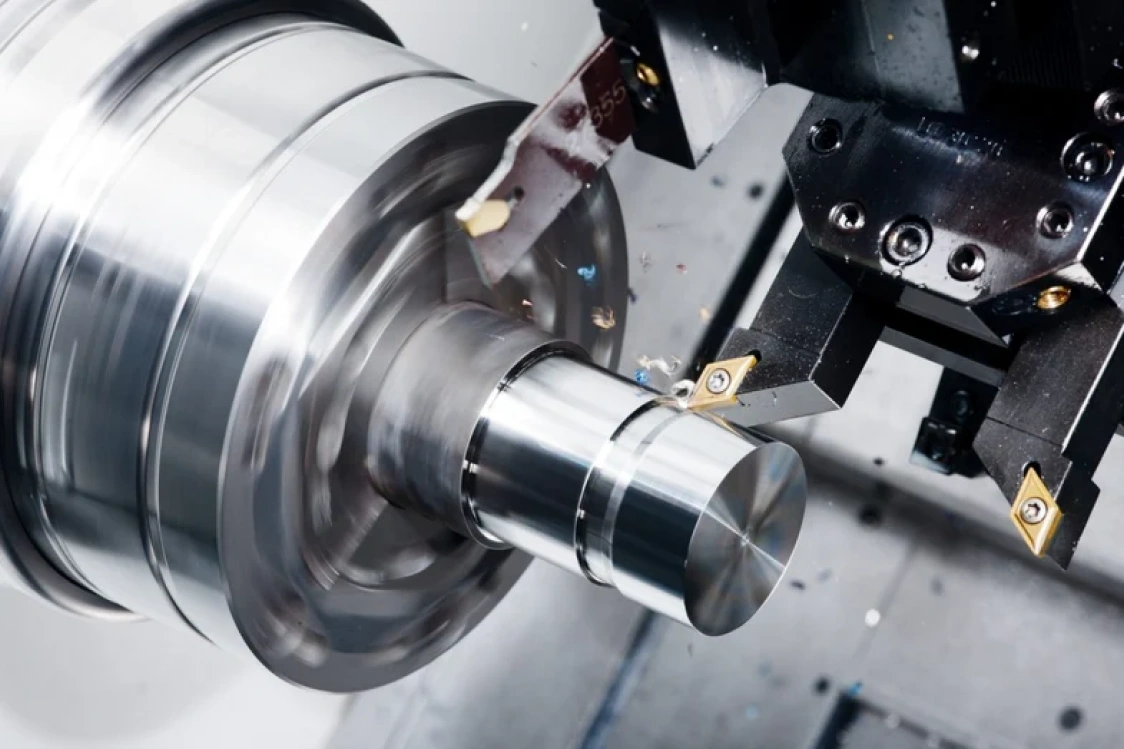

Our CNC turning/lathe centers deliver:

• Tolerances down to ±0.0002″ (0.005mm).

• Sample parts are ready in as little as 1 day.

• Access to over 50 types, including metals and polymers.

• Advanced lathe and live tooling for High-Quality turned parts.

Our CNC Turning Service

KingTeam offers CNC turning services using advanced CNC lathes with live tooling, which is ideal for

creating axial and radial holes, flats, grooves, and slots. Here's what we provide:

• Rapid Turnaround: CNC turning service with a 1-day lead time for prototypes.

• Precision Capabilities: Perfect for functional prototypes, final-use parts, and components requiring

precise cylindrical or symmetrical features.

• Material Versatility: On-demand manufacturing of metal or plastic parts, suitable for both prototyping and

full-scale production runs.

• Certifications: Upon request, we provide certificates of conformity, raw material certifications, and

detailed measurement reports to meet client specifications.

Our CNC Lathe Capabilities

Factors | Tech. Specifications | |

Anodizing Types | MIL-A-8625 Type II, Class 1 (Clear); MIL-A-8625 Type II, Class 2 (Black); MIL-A-8625 Type III, Class 1 (Clear); MIL-A-8625 Type III, Class 2 (Black); MIL-A-8625 Type II, Class 2 (Other Colors); MIL-A-8625 Type III, Class 2 (Other Colors) | |

Plating | Chromium, Nickel, Zinc, Copper, Gold, Silver, Tin, Cadmium; etc. | |

Part Diameter | Minimum 0.5 mm(0.02 in); Maximum 300 mm(11.8 in) | |

Part Length | Minimum 1.0 mm(0.04 in); Maximum 600 mm(23.6 in) | |

Maximum Swing Over Carriage | 350 mm (13.7 in) | |

Maximum Spindle Through-Hole | 40 mm (1.5 in) | |

Design Tolerances | ±0.0002 in(±0.005 mm) |

How does CNC Turning Work?

Please find below a brief overview of how turning operations work.

Step 01: Converting CAD Design to CNC Program: Step 03: Optimizing Speed and Feed Rate:

Our engineers utilise CAD tools such as AutoCAD or SolidWorks Our highly trained operators adjust the turning speed and

to create the initial design, which is then transferred with precision feed rate after determining that the current speed is sufficient

to a CNC program for cutting. to achieve the desired surface finish and tolerance.

Step 02: CNC Turning Machine Setup: Step 04: Precision Manufacturing:

Our lathe machining experts guarantee precise workpiece CNC turning requires meticulous attention to detail and precise

positioning and tool selection, thus ensuring accuracy when control of each stage, from loading to cutting, to produce parts

uploading the CNC program. with complex shapes.

How to Order Parts?

Obtain a complimentary quotation from a genuine engineer. Upon receipt of your design, our engineer will conduct a review and provide you with a quotation within one hour.

① Get A Quote Immediately

Send your design directly to us by email, specifying the production requirements of the part and get a quote within an hour at the earliest.

② Start Production

Your parts will be made once your orders are confirmed. Besides, we will give you regular feedback on the production status of your order.

③ Receive Your Part

After all parts pass QC inspection, they will be well packed from transportation accidents. Then, your custom parts are delivered straight to your doorstep.

▲ We generally evaluate production and provide quotations within six hours. If you need a more urgent quote within 1 hour, please contact us directly through our official WhatsApp account or Phone for immediate communication.

CNC Turning Materials

Brass

Brass offers high strength and hardness, along with excellent electrical and thermal conductivity.

Commonly used brass grades include C36000 (CW509L), C26000 (CW507L), and C22000 (CW505L).

Aluminum

Aluminum is suitable for manufacturing lightweight components, such as aerospace parts,

automotive components, and electronic product enclosures. Commonly used grades include

6061 (AlMg1SiCu), 7075 (AlZn5.5MgCu), and 2024 (AlCu4MgSi).

Low Carbon Steel

Low-carbon steel can be used in general-purpose parts, including auto brackets and machine parts.

C45 steel, after heat treatment, achieves high strength and hardness, making it suitable for

manufacturing parts that require high strength and wear resistance.

Steel Alloy

Steel alloys, such as gears and shafts, are used in applications requiring strength. 4140 (42CrMo4)

has high hardenability, toughness, and wear resistance for specific applications.

Stainless Steel

Stainless steel is suitable for use in corrosive environments and offers high strength and hardness.

430 (X6Cr17) plays an indispensable role in metal components for household appliances.

Titanium

Titanium is used when a high strength-to-weight ratio is required, such as in aircraft manufacture

and the medical field. Grade 2 (3.7035) and Grade 5 (3.7165) are strong and corrosion-resistant.

Plastics

The custom housings and device prototypes use ABS and polycarbonate (PC). PEEK' s high performance

is in application areas that require high strength and toughness.

CNC Lathe Part Finishing Options

Standard (As-Milled) Polishing Bead Blast

The finish option with the quickest turnaround. Polishing can be performed through electrochemical High-speed blasting with fine particles removes

Sharp edges and burrs would be removed. and mechanical methods. It produces a smooth, oxidation layers, rust, burrs, and other imperfections

refined mirror-like finish,reducing friction and wear on from the surface of parts, achieving the desired

the surface of the parts. This level of surface finish is surface quality and roughness.

the preferred choice for machined components.

Anodized Powder coating Black-Oxide

Type II anodized is cost-effective and is Powder coating applies durable paint baked on Black oxide treats ferrous materials, creating

available in clear, black, red or gold, primarily for wear and corrosion resistance. It is available a sleek black, mildly corrosion-resistant oxide

for aluminum. Type III adds additional in any RAL/Pantone color. Thickness: 18-72 µm layer. It is ideal for precision components

abrasion and corrosion resistance. needing a low-reflective, durable surface and

preserves tight tolerances.

More Surface Finishing Options

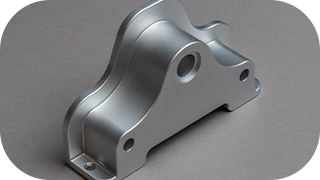

• High Precision Tolerances • Scalability Custom • Surface Finishes

Kingteam offers excellent accuracy, We offer capabilities for small sample Upgrade your components with Kingteam's

with tolerance levels of ±0.0002″, orders and large orders of up to selection of bespoke surface coatings. We

depending on requirements. We pride 100,000 parts and handle the easy offer different finishing services that can be

ourselves on producing complex transition from testing prototyping to applied to various materials to meet your

components with exacting standards. mass production. parts' aesthetic and functional needs.