We're delighted to share that we shipped a batch of CNC automotive parts overseas yesterday! Watch the video to see how our team is working hard to get everything ready for shipping.

Our Successful Year-End Party and Celebration for 2025!

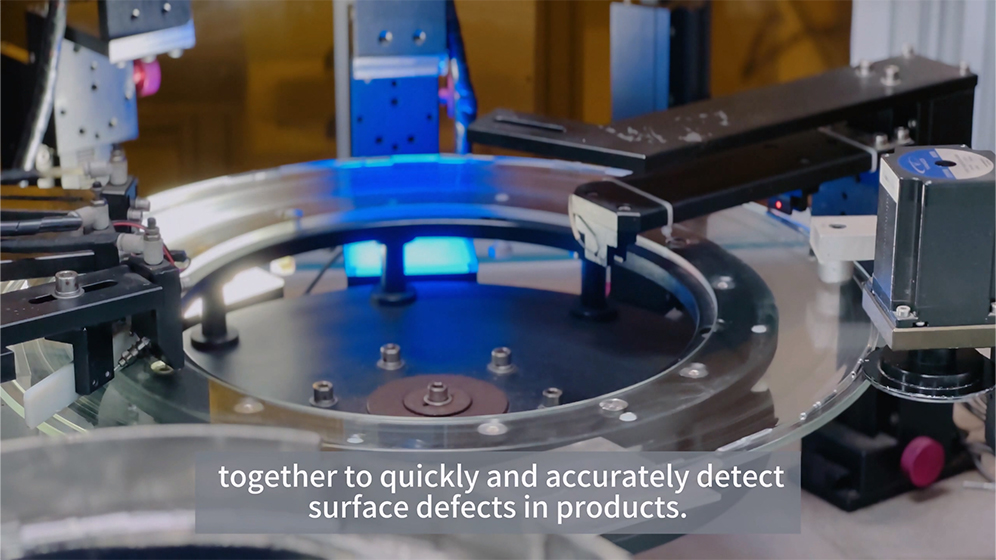

In a fast-paced production line, precise quality control is key to success. Our Automatic Optical Inspection (AOI) system uses high-precision cameras and computer vision technology to ensure every part meets the highest standards. Whether it's small or large batch production, we guarantee high efficiency and top-quality results, ensuring on-time delivery and peace of mind for our customers. See how innovation drives productivity and helps us craft precision components!

To ensure the accuracy of our products and avoid contamination of the workpiece by cutting oil or debris, our technicians perform an air-blowing process on the fixtures after machining. The finished workpieces are visually inspected before being sent to the quality control center for a full inspection. Even with these steps, our production efficiency remains unaffected. Our technicians are professionally trained and have extensive operational experience, allowing one technician to manage multiple CNC machines while maintaining product quality without sacrificing efficiency.

Today, our star is a 6061 (AlMg1SiCu) aluminum bar. Using our CNC machining center, we will transform this simple aluminum bar into 10 precision components.