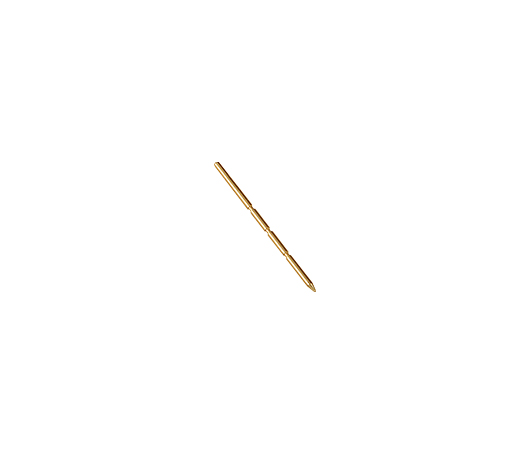

The conductive pins are commonly used in electronic products, serving as part of printed circuit boards and assemblies. The manufacturing process mainly involves CNC turning and machining. These components are made from C36000, with one of the surface treatments being gold plating. We can produce these conductive pins using carbon steel or brass, with surface treatment options including eco-friendly nickel plating and gold plating.

If you are interested, please feel free to contact us and let us know your requirements.

E-mail: hzbusiness@kingteam-cn.com

KINGTEAM has 23 years of experience in micron-level CNC precision metal machining, producing over 1 million precision CNC machined parts and 2.5 million forged parts per week. To ensure overall quality for our customers, we control every step of the part manufacturing process in-house. Our expertise covers a wide range of processes, including machining, turning, milling, forging, stamping, tooling and splitting, high-speed cutting, as well as heat treatment and surface finishing. This extensive technical knowledge sets our products apart and enables us to provide innovative and reliable solutions to our clients.

Our conductive pin components offer significant advantages in terms of low contact resistance, conductivity, durability. They ensure stable signal transmission with a low failure rate, improve energy efficiency, and extend the lifespan of devices, making them suitable for various demanding environments. Manufactured using high-quality materials such as carbon steel and advanced surface treatments like eco-friendly nickel plating or gold plating, these pins are designed to withstand harsh conditions and frequent operation. This allows electronic devices to reliably perform in high-demand industries such as industrial, aerospace, and military applications.

We also support customization and can manufacture complex flashlight components according to specific application requirements, including custom dimensions, shapes, and surface treatments. These components enable flashlights to perform exceptionally well in outdoor, industrial, and other application scenarios.

Partner and supplier to numerous Tier 1 suppliers and original equipment manufacturers (OEMs), we cater to global demands based on our product range. Our project team works closely with clients to design parts that fully meet their specifications, taking into account all capabilities and constraints of the manufacturing processes.

Services provided | |

Supply Material | Aluminium: 2024, 6061 Carbon steel: 1010, 1045, 1213, 1215, 12L14 Alloy steel: 4140 Stainless Steel: 303, 304, 416, 420, 430F Brass: C36000, C2604, C3604 (Accept customization with other materials) |

Surface Finishes | painting, baking paint, powder coating, sandblasting, shot peening, anodizing, thick film oxidation, micro-arc oxidation, electroplating, electrophoresis,laser engraving, silk-screen printing, brushing, mirror polishing, coloring, blackening , CD pattern, etching, high-gloss machining, texturing, epoxy coating. |

Products | Processing range |

Lathe Turned Products | Outer diameter 0.5 mm-300 mm ; Length 1.0 mm-600 mm ; With tolerance up to +/-0.005 mm ; |

CNC Machining Center | Maximum Dimension: L800 * W500 * H300 mm ; Tolerance up to +/-0.005 mm ; |

Precise Stampin | Tonnage Range: 10 T-200 T ; Tolerance up to +/-0.01 mm ; |

Centerless Grinding Processing | Outer diameter range: φ1.0 mm to φ150 mm ; Outer diameter tolerance up to +/-0.001mm ; |