Automated Hole Depth Inspection Machines ensure ±0.005mm accuracy in blind hole measurements, eliminating human error with real-time data feedback. Paired with Automated Optical Inspection (AOI) Machines, they deliver non-contact 3D scanning for surface defects and complex geometries. Together, these systems reduce 90% inspection time, integrate with production lines, and generate traceable quality reports.

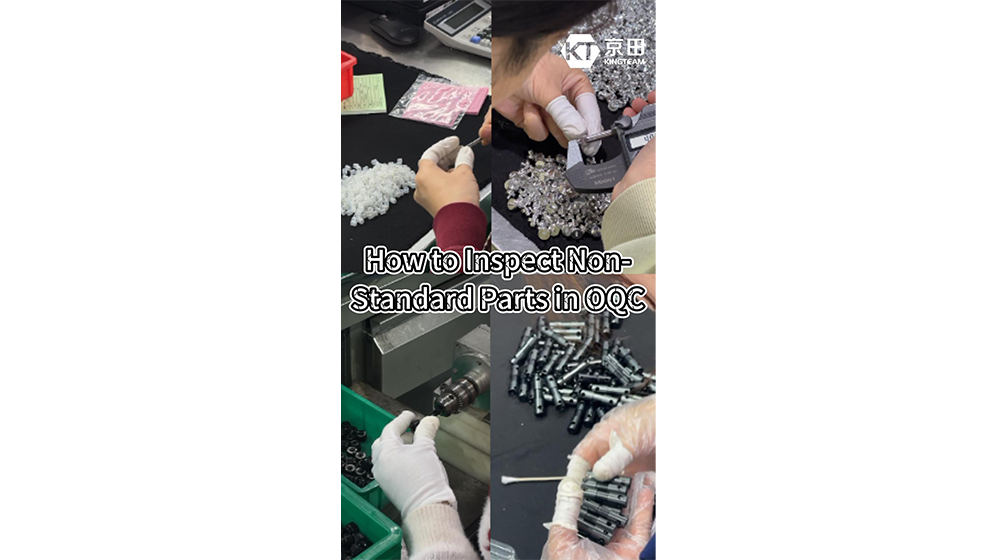

Unlike mass-produced goods, each piece undergoes strict checks: custom specs validation, functional testing, and compatibility audits. This final gatekeeper ensures deviations are caught, materials meet standards, and unique designs perform flawlessly.

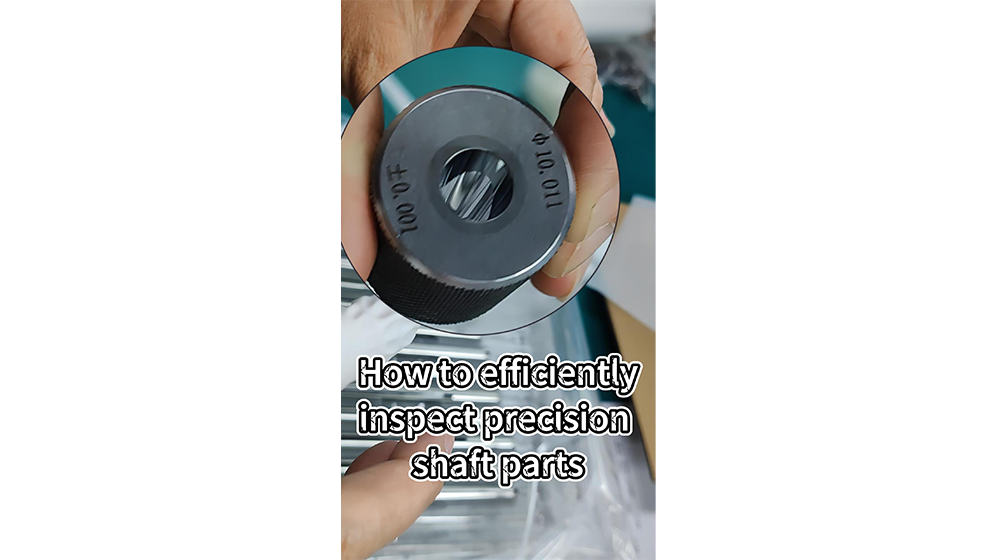

Plain ring gauges are not only capable of checking tolerances as tight as ±0.0002"(±0.005mm), but they’re also incredibly fast and efficient. They’re perfect for first-article inspection (FAI), in-process checks, and final inspection on production lines.

This is the surface roughness of our freshly machined part. A smoother surface (lower roughness) means slower wear and longer product lifespan.

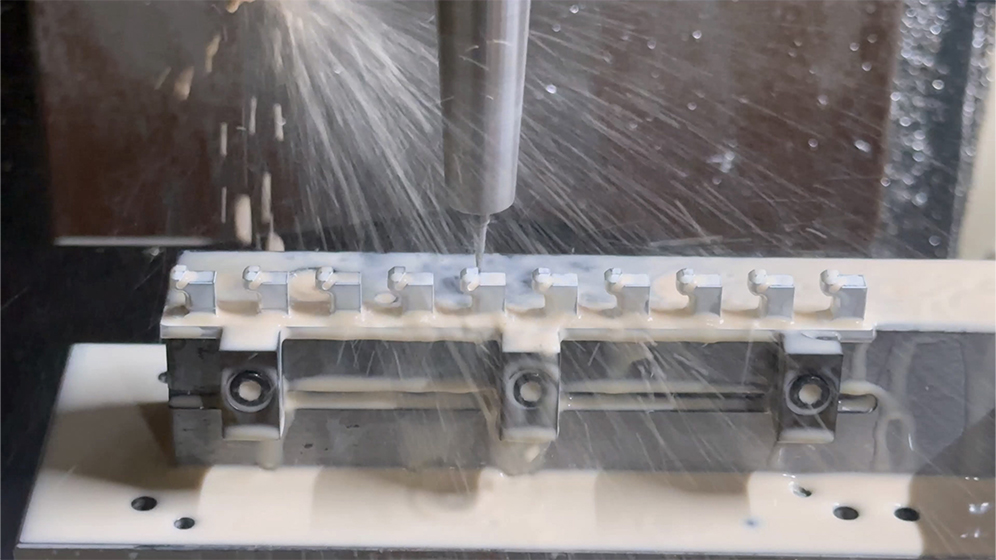

Today, we’re performing a second machining operation on the aluminum parts from our previous video. We’ve created a custom fixture that allows us to machine 20 precision parts in a single batch.

Today, our star is a 6061 (AlMg1SiCu) aluminum bar. Using our CNC machining center, we will transform this simple aluminum bar into 10 precision components.